- Home Page

- Company Profile

-

Our Products

- Castor Oil Derivatives

- Cetyl Ricinoleate Supplier

- Ethyl Undecanoate

- Heptanoic Acid

- Methyl Undecanoate - Exporter

- Zinc Ricinoleate Exporter

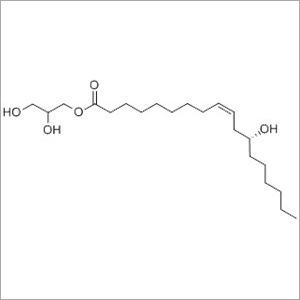

- Glyceryl Monoricinoleate Exporter

- Glyceryl Mono Undecylenate - Exporter

- Heptyl Undecylenate Supplier

- Methyl Ricinoleate - Manufacturer

- Polyricinoleic Acid - Manufacturer

- Pentaerythritol Mono Ricinoleate- Supplier

- Ricinoleic Acid - Manufacturer

- Undecanoic Acid 98% Min. By GC

- Alcohol C-11 Undecylenic

- Methyl Undecylenate 98% Min. Purity By GC

- Undecylenic Acid

- Zinc Undecylenate as per BP/EP/USP

- Butyl Ricinoleate - Manufacturer

- Calcium Ricinoleate

- Calcium Undecylenate as per USP

- Heptaldehyde 97% Min. By GC

- Heptyl Alcohol 98%Min.By GC

- Methyl Acetyl Ricinoleate - Supplier

- Aldehyde C11 Undecylenic

- Butyl Undecylenate

- Castor Oil

- Condensed Ricinoleic Acid

- Ethyl Undecylenate

- Glyceryl Mono Undecenoate - Castor Oil Derivative

- Sodium Undecylenate

- Chromatographic Adsorbents

- Fatty Acid Esters & Salts

- Zinc Ricinoleate Supplier

- Methyl Oleate - Supplier

- Cetyl Ricinoleate Manufacturer

- Glyceryl Monoricinoleate Supplier

- Glyceryl Mono Undecylenate Manufacturer

- Heptyl Undecylenate Manufacturer

- Methyl Ricinoleate

- Pentaerythritol Mono Ricinoleate

- Butyl Oleate 99% Min. By GC

- Methyl Undecylenate - Supplier

- Butyl Ricinoleate

- Methyl Acetyl Ricinoleate - Manufacturer

- Butyl Oleate Commercial

- Methyl Oleate Commercial- Supplier

- Behenic Acid Methyl Ester

- Caprylic Acid

- Erucic Acid

- Lauric Acid

- Methyl Heptanoate

- Oleic Acid Ethyl Ester

- Palmitic Acid

- Potassium Oleate

- Sodium Caprylate - Supplier

- Soya Oil Methyl Ester

- Stearic Acid

- Arachidic Acid Ethyl Ester - Supplier

- Elaidic Acid Methyl Ester

- Glyceryl Mono Undecenoate - Supplier

- Linoleic Acid Methyl Ester 99% Min. By GC

- Methyl Undecanoate

- Palmitic Acid Methyl Ester

- Sodium Oleate

- Potassium Caprylate

- Stearic Acid Methyl Ester

- Behenic Acid Ethyl Ester

- Linoleic Acid Ethyl Ester

- Fatty Alcohols

- Lipid Chemicals

- Arachidic Acid 99% Min By GC

- Elaidic Acid 99% Min. By GC

- Linoleic Acid 99% Min. By GC

- Methyl Oleate 99% Min. By GC

- Oleic Acid 99% Min.By GC

- Methyl Oleate Commercial

- Arachidic Acid Methyl Ester

- Arachidic Acid Ethyl Ester

- Elaidyl Alcohol - Manufacturer

- Linoleyl Alcohol - Manufacturer

- Linoleic Acid Ethyl Ester - Manufacturer

- Odor Absorbers

- Ricinoleates

- Zinc Ricinoleate Manufacturer

- Cetyl Ricinoleate Exporter

- Glyceryl Monoricinoleate Manufacturer

- Methyl Ricinoleate - Supplier

- Pentaerythritol Mono Ricinoleate- Manufacturer

- Polyricinoleic Acid

- Ricinoleic Acid

- Butyl Ricinoleate - Supplier

- Calcium Ricinoleate - Manufacturer

- Methyl Acetyl Ricinoleate - Exporter

- Cosmetic Ingredients

- Undecylenic Acid - Cosmetics

- Zinc Ricinoleate

- Potassium Caprylate - Cosmetics

- Cetyl Ricinoleate

- Glyceryl Monoricinoleate

- Heptyl Undecylenate

- Undecanoic Acid - Cosmetics

- Undecylenic Monoethanolamide - Cosmetics

- Zinc Undecylenate - Cosmetics

- Methyl Acetyl Ricinoleate

- Aldehyde C11 Undecylenic - Cosmetics

- Arachidyl Alcohol - Cosmetics

- Behenic Acid Methyl Ester - Cosmetics

- Caprylic Acid - Cosmetics

- Erucic Acid - Cosmetics

- Lauric Acid - Cosmetics

- Methyl Heptanoate - Cosmetics

- Oleic Acid Ethyl Ester - Cosmetics

- Oleyl Alcohol - Cosmetics

- Palmitic Acid - Cosmetics

- Potassium Oleate - Cosmetics

- Sodium Caprylate - Cosmetics

- Soya Oil Methyl Ester - Cosmetics

- Stearic Acid - Cosmetics

- Butyl Undecylenate - Cosmetics

- Castor Oil - Cosmetics

- Glyceryl Mono Undecenoate - Cosmetics

- Heptanoic Acid - Cosmetics

- Linoleic Acid Methyl Ester - Cosmetics

- Palmitic Acid Methyl Ester - Cosmetics

- Sodium Oleate - Cosmetics

- Sodium Undecylenate - Cosmetics

- Stearic Acid Methyl Ester - Cosmetics

- Linoleic Acid Ethyl Ester - Cosmetics

- Emollient

- Cetyl Ricinoleate - Cosmetics

- Glyceryl Mono Undecylenate-Cosmetics

- Glyceryl Monoricinoleate - Cosmetics

- Heptyl Undecylenate - Cosmetics

- Methyl Acetyl Ricinoleate - Cosmetics

- Erucic Acid - Emollient

- Oleic Acid Ethyl Ester - Manufacturer

- Palmitic Acid - Exporter

- Ethyl Undecylenate - Manufacturer

- Glyceryl Mono Undecenoate - Manufacturer

- Palmitic Acid Methyl Ester - Supplier

- Stearic Acid Methyl Ester - Exporter

- Personal Care Ingredients

- Cetyl Ricinoleate - Personal Care Product

- Glyceryl Monoricinoleate- Personal Care Product

- Heptyl Undecylenate - Personal Care Product

- Methyl Acetyl Ricinoleate - Personal Care Product

- Aldehyde C11 Undecylenic - Exporter

- Arachidyl Alcohol - Manufacturer

- Behenic Acid Methyl Ester - Manufacture

- Caprylic Acid - Manufacturer

- Lauric Acid - Personal Care Product

- Oleic Acid Ethyl Ester - Personal Care Product

- Oleyl Alcohol - Manufacturer

- Palmitic Acid - Manufacturer

- Potassium Oleate - Manufacturer

- Soya Oil Methyl Ester - Manufacturer

- Stearic Acid - Manufacturer

- Palmitic Acid Methyl Ester - Manufacturer

- Sodium Oleate - Supplier

- Sodium Undecylenate - Supplier

- Natural Preservatives

- Undecylenates

- Glyceryl Mono Undecylenate-Supplier

- Heptyl Undecylenate Exporter

- Undecanoic Acid 98% Min. By GC - Manufacturer

- Sodium Undecylenate - Manufacturer

- Methyl Undecylenate 98% Min. By GC - Manufacturer

- Undecylenic Acid - Manufacturer

- Zinc Undecylenate - Manufacturer

- Calcium Undecylenate - Manufacturer

- Butyl Undecylenate - Supplier

- Castor Oil - Manufacturer

- Ethyl Undecylenate - Supplier

- Glyceryl Mono Undecenoate - Exporter

- Skin Care Products

- Glyceryl Mono Undecylenate- Skin Care Product

- Zinc Ricinoleate- Skin Care Product

- Glyceryl Monoricinoleate- Skin Care Product

- Heptyl Undecylenate - Skin Care Product

- Calcium Ricinoleate - Supplier

- Methyl Acetyl Ricinoleate - Skin Care Product

- Cetyl Ricinoleate - Skin Care Product

- Aldehyde C11 Undecylenic - Supplier

- Arachidyl Alcohol - Supplier

- Behenic Acid Methyl Ester - Supplier

- Caprylic Acid - Supplier

- Oleic Acid Ethyl Ester - Skin Care Product

- Oleyl Alcohol - Exporter

- Palmitic Acid - Supplier

- Potassium Oleate - Supplier

- Soya Oil Methyl Ester - Supplier

- Stearic Acid - Supplier

- Castor Oil - Supplier

- Glyceryl Mono Undecenoate - Skin Care Product

- Palmitic Acid Methyl Ester - Exporter

- Stearic Acid Methyl Ester - Manufacturer

- Emulsifier

- Glyceryl Monoricinoleate - Emulsifier

- Glyceryl Mono Undecylenate - Emulsifier

- Zinc Ricinoleate - Emulsifier

- Ricinoleic Acid - Emulsifier

- Undecanoic Acid - Emulsifier

- Linoleic Acid - Emulsifier

- Methyl Oleate - Emulsifier

- Oleic Acid - Emulsifier

- Undecylenic Acid - Emulsifier

- Heptaldehyde - Emulsifier

- Silica Gel for Column Chromatography - Emulsifier

- Arachidic Acid - Emulsifier

- Methyl Oleate Commercial- Emulsifier

- Caprylic Acid - Emulsifier

- Lauric Acid - Emulsifier

- Methyl Heptanoate - Emulsifier

- Oleyl Alcohol - Emulsifier

- Palmitic Acid - Emulsifier

- Potassium Oleate - Emulsifier

- Sodium Caprylate - Emulsifier

- Stearic Acid - Emulsifier

- Castor Oil - Emulsifier

- Glyceryl Mono Undecenoate - Emulsifier

- Linoleic Acid Methyl Ester - Emulsifier

- Palmitic Acid Methyl Ester - Emulsifier

- Sodium Oleate - Emulsifier

- Potassium Caprylate - Emulsifier

- Sodium Undecylenate - Emulsifier

- Stearic Acid Methyl Ester - Emulsifier

- Hair Care Products

- Heptyl Undecylenate- Hair Care Product

- Zinc Ricinoleate- Hair Care Product

- Butyl Oleate - Hair Care Product

- Linoleic Acid - Hair Care Product

- Butyl Oleate Commercial -Supplier

- Oleic Acid - Supplier

- Undecylenic Acid - Supplier

- Arachidic Acid - Hair Care Product

- Lauric Acid - Exporter

- Oleic Acid Ethyl Ester - Supplier

- Oleyl Alcohol - Supplier

- Stearic Acid - Exporter

- Sodium Undecylenate - Exporter

- Stearic Acid Methyl Ester - Supplier

- Lubricants

- Glyceryl Monoricinoleate - Lubricant

- Heptyl Undecylenate Lubricant

- Methyl Ricinoleate - Lubricant

- Polyricinoleic Acid - Lubricant

- Pentaerythritol Mono Ricinoleate - Lubricant

- Ricinoleic Acid - Lubricant

- Butyl Oleate - Lubricant

- Butyl Oleate Commercial- Lubricant

- Methyl Undecylenate - Lubricant

- Butyl Ricinoleate - Lubricant

- Methyl Acetyl Ricinoleate - Lubricant

- Behenic Acid Methyl Ester - Lubricant

- Caprylic Acid - Lubricant

- Erucic Acid - Lubricant

- Lauric Acid - Lubricant

- Oleyl Alcohol - Lubricant

- Potassium Oleate - Lubricant

- Soya Oil Methyl Ester - Lubricant

- Stearic Acid - Lubricant

- Castor Oil - Lubricant

- Heptanoic Acid - Lubricant

- Linoleic Acid Methyl Ester - Lubricant

- Palmitic Acid Methyl Ester - Lubricant

- Sodium Oleate - Lubricant

- Stearic Acid Methyl Ester - Lubricant

- Textile Chemicals

- Leather Chemicals

- Pharma Ingredients

- Zinc Undecylenate - Pharma Ingredient

- Undecylenic Acid - Pharma Ingredient

- Caprylic Acid - Pharma Ingredient

- Undecylenic Monoethanolamide

- Calcium Undecylenate - Pharma Ingredient

- Lauric Acid - Pharma Ingredient

- Sodium Caprylate - Manufacturer

- Castor Oil - Pharma Ingredient

- Heptanoic Acid - Supplier

- Sodium Oleate - Manufacturer

- Anti Fungals

- Undecylenic Acid - Antifungal

- Zinc Undecylenate - Anti Fungal

- Undecanoic Acid - Anti Fungal

- Undecylenic Monoethanolamide - Anti Fungal

- Calcium Ricinoleate - Anti Fungal

- Calcium Undecylenate - Anti Fungal

- Caprylic Acid - Anti Fungal

- Lauric Acid - Anti Fungal

- Sodium Caprylate - Anti Fungal

- Castor Oil - Anti Fungal

- Nail Care Product

- Separation Aids

- Perfumery Chemicals

- Alcohol C-11 Undecylenic - Supplier

- Methyl Undecylenate - Exporter

- Heptaldehyde - Manufacturer

- Heptyl Alcohol - Supplier

- Ethyl Undecylenate - Exporter

- Aldehyde C11 Undecylenic - Manufacturer

- Caprylic Acid - Exporter

- Methyl Heptanoate - Supplier

- Oleic Acid Ethyl Ester - Exporter

- Butyl Undecylenate - Manufacturer

- Castor Oil - Perfumery Chemical

- Ethyl Undecanoate - Manufacturer

- Linoleic Acid Methyl Ester - Exporter

- Heptanoic Acid - Manufacturer

- Methyl Undecanoate - Manufacturer

- Linoleic Acid Ethyl Ester - Exporter

- Fragrance Chemicals

- Alcohol C-11 Undecylenic - Exporter

- Heptyl Alcohol - Exporter

- Butyl Oleate - Fragrance Chemical

- Butyl Oleate Commercial - Manufacturer

- Methyl Undecylenate - Perfume & Fragrance Chemical

- Heptaldehyde - Supplier

- Aldehyde C11 Undecylenic - Perfumes & Fragrances

- Caprylic Acid - Perfumes & Fragrances

- Methyl Heptanoate - Perfumes & Fragrances

- Oleic Acid Ethyl Ester - Perfumes & Fragrances

- Castor Oil - Fragrance Chemical

- Ethyl Undecanoate - Supplier

- Ethyl Undecylenate - Perfumes & Fragrances

- Heptanoic Acid - Exporter

- Linoleic Acid Methyl Ester - Supplier

- Methyl Undecanoate - Supplier

- Linoleic Acid Ethyl Ester - Perfumes & Fragrances

- Nutritional Supplements

- Arachidic Acid - Pharmaceutical Chemical

- Elaidic Acid - Pharmaceutical Chemical

- Linoleic Acid - Pharmaceutical Chemical

- Methyl Oleate - Pharmaceutical Chemical

- Oleic Acid - Pharmaceutical Chemical

- Arachidic Acid Methyl Ester - Supplier

- Elaidyl Alcohol - Supplier

- Lauric Acid - Supplier

- Linoleyl Alcohol - Exporter

- Methyl Heptanoate - Manufacturer

- Oleic Acid Ethyl Ester - Pharmaceutical Chemical

- Oleyl Alcohol - Pharmaceutical Chemical

- Sodium Caprylate

- Linoleic Acid Methyl Ester - Manufacturer

- Specialty Fatty Acid

- Arachidic Acid - Manufacturer

- Elaidic Acid - Manufacturer

- Linoleic Acid - Manufacturer

- Methyl Oleate - Manufacturer

- Oleic Acid - Manufacturer

- Methyl Oleate Commercial - Manufacturer

- Arachidic Acid Methyl Ester - Manufacturer

- Arachidic Acid Ethyl Ester - Manufacturer

- Elaidyl Alcohol - Exporter

- Lauric Acid - Manufacturer

- Linoleyl Alcohol - Supplier

- Linoleic Acid Ethyl Ester - Supplier

- Aldehydes

- Silica Gel for Column Chromatography

- Silica Gel for Thin Layer Chroamtography

- Castor Oil Derivatives

- Contact Us

Ricinoleic Acid - Lubricant

Product Details:

- Chemical Composition Ricinoleic Acid (C18H34O3) - major component

- Use Lubricant for machinery, processing equipment, specialty applications

- Grease Base for specialty greases

- Density 0.970 Gram per cubic centimeter(g/cm3)

- Water Content Vol% Max 0.5%

- Ash % Max 0.02%

- Smell Mild, characteristic odor

- Click to view more

X

Ricinoleic Acid - Lubricant Product Specifications

- Lubrication, surface protection, metalworking, plastics, cosmetics

- 220-270 mPas (at 25C)

- Pale yellow to light brown

- Sealed drums, bulk storage

- -10C to 80C

- 50 kg (standard drum)

- Drum, bulk container

- Suitable for industrial and automotive applications

- Vegetable-Based Oil

- Mild, characteristic odor

- Lubricant

- Max 0.02%

- Max 0.5%

- 50 kg, 200 kg drum options

- 0.970 Gram per cubic centimeter(g/cm3)

- Ricinoleic Acid (C18H34O3) - major component

- Base for specialty greases

- Lubricant for machinery, processing equipment, specialty applications

Product Description

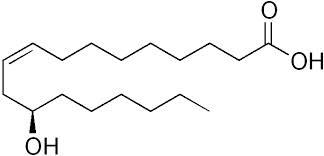

RICINOLEIC ACID | |

PARAMETERS | SPECIFICATIONS |

Synonyms | 12-Hydroxy-Cis-9-Octadecenoic Acid |

CAS No | 141-22-0 |

Formula | C18H34O3 |

Mol. Wt | 298.35 |

Description | Clear Slightly Hazy Pale Yellow Liquid at 25o C |

Color | 8 Gardner Max |

Acid Value | 26 Max |

Hydroxyl Value | 28 Max |

| Packaging | The material will be packed in plastic open mouth drums with ring and lid, with poly bags on the inside, of Net 30 KGS each. |

(NOTE: WE CAN PROVIDE MORE BETTER SPECIFICATION OF RICINOLEIC ACID AS PER PARTY'S REQUIREMENT.)

Acme Synthetic Chemicals is the Manufacturer, Supplier & Exporter of Ricinoleic Acid which is classified under CAS NO.141-22-0.

Ricinoleic Acid - Lubricant (CAS No.141-22-0) is also known as 12-hydroxy-9-cis-octadecenoic acid.

Acme Synthetic Chemicals is one of the reputed organizations engaged in providing superior quality Ricinoleic Acid - Lubricant (CAS No.141-22-0, 12-hydroxy-9-cis-octadecenoic acid) to our esteemed clients.

Ricinoleic Acid - Lubricant (CAS No.141-22-0, 12-hydroxy-9-cis-octadecenoic acid) is an unsaturated omega-9 fatty acid that naturally occurs in mature Castor plant (Ricinus communis L., Euphorbiaceae) seeds.

Ricinoleic Acid - Lubricant (CAS No.141-22-0, 12-hydroxy-9-cis-octadecenoic acid) is the active component of castor oil.

Ricinoleic Acid - Lubricant (CAS No.141-22-0, 12-hydroxy-9-cis-octadecenoic acid) is prepared by the hydrolysis of Castor Oil.It is used in textile finishing, in coating, inks and in making soaps.

Ricinoleic Acid - Lubricant (CAS No.141-22-0, 12-hydroxy-9-cis-octadecenoic acid) is used to manufacture Poly Glyceryl Poly Ricinoleate (PGPR) a key ingredient in chocolate products.

Ricinoleic Acid - Lubricant (CAS No.141-22-0, 12-hydroxy-9-cis-octadecenoic acid) is used for the treatment of leather.

Ricinoleic Acid - Lubricant (CAS No.141-22-0, 12-hydroxy-9-cis-octadecenoic acid) provides good wetting, flexibility and softening property to leather.

Ricinoleic Acid - Lubricant (CAS No.141-22-0, 12-hydroxy-9-cis-octadecenoic acid) contains antimicrobial properties, which, when applied to open wounds, can act as a disinfectant.

Ricinoleic Acid - Lubricant (CAS No.141-22-0, 12-hydroxy-9-cis-octadecenoic acid) is effective for treating fungal skin infections, such as ringworm, as well as minor cuts and scratches.

The offered product Ricinoleic Acid - Lubricant (CAS No.141-22-0, 12-hydroxy-9-cis-octadecenoic acid) is formulated using supreme class ingredients and modern techniques by our team of skilled professionals as per the set industry norms at our state-of-the-art processing unit.

This Ricinoleic Acid - Lubricant (CAS No.141-22-0, 12-hydroxy-9-cis-octadecenoic acid) is widely demanded in the international market due to its high effectively, eco-friendliness & purity, and is offered in different grades to meet the varied needs of our clients. Moreover, we are offering the entire range at an affordable cost to our clients.

Superior Lubrication Across Industries

Designed for industrial and automotive applications, Ricinoleic Acid Lubricant delivers reliable performance in machinery, processing equipment, and specialty uses. Its high purity and steady viscosity ensure optimum lubrication, surface protection, and compatibility with plastic and metalworking processes. The product excels as a base for specialty greases and extends service intervals by resisting high temperature fluctuations and oxidation.

Eco-Friendly, High-Performance Formulation

Sourced from vegetable-based oil, ricinoleic acid is not only biodegradable but also safe for both users and the environment. Perfect for industries seeking sustainability without compromising operational efficiency. Its low water and ash content guarantees minimal residue and optimal equipment function over extended periods.

Easy Handling and Storage

Ricinoleic Acid Lubricant is available in standard size drums (50 kg / 200 kg) with packaging designed for safe bulk storage and transportation. Its stability under a wide range of operating temperatures (-10C to 80C) and protection against degradation (when stored in a cool, dry location away from sunlight) ensures a shelf life of up to two years.

FAQs of Ricinoleic Acid - Lubricant:

Q: How is Ricinoleic Acid Lubricant applied in industrial settings?

A: Ricinoleic Acid Lubricant can be directly used for machinery lubrication, surface protection, or as a base for specialty greases in processing equipment. It is typically introduced into lubrication systems by conventional means, ensuring consistent protection and smooth operation.Q: What benefits does this lubricant offer over conventional mineral-based oils?

A: Being vegetable-based and readily biodegradable, Ricinoleic Acid Lubricant offers environmental advantages, stable viscosity, and resistance to oxidation at high temperatures. It reduces residue due to low water and ash content, making it reliable for extended machinery life and clean operation.Q: When should Ricinoleic Acid Lubricant be used for optimal performance?

A: For optimal results, use the lubricant within its two-year shelf life, under operating temperatures from -10C to 80C. Ensure the product is stored correctly in sealed drums to maintain purity and effectiveness.Q: Where can Ricinoleic Acid Lubricant be stored safely?

A: Store Ricinoleic Acid Lubricant in a cool, dry place, away from direct sunlight and heat sources, in its original sealed drum or bulk container. Proper storage prevents degradation and preserves product quality.Q: What is the process for handling and packaging Ricinoleic Acid Lubricant?

A: The lubricant is supplied in sealed drums of 50 kg or 200 kg, designed for bulk handling and easy transport. During packaging, care is taken to minimize exposure to moisture and contaminants.Q: How is Ricinoleic Acid Lubricant used in grease formulation?

A: Its high purity and stable chemical composition make Ricinoleic Acid an exceptional base for specialty greases, providing consistency, longevity, and improved performance for demanding industrial applications.Q: What industries benefit most from Ricinoleic Acid Lubricant?

A: Industries such as automotive, metalworking, plastics manufacturing, and cosmetics find this lubricant valuable due to its versatility, environmental compatibility, and robust lubrication properties.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email