- Home Page

- Company Profile

-

Our Products

- Castor Oil Derivatives

- Cetyl Ricinoleate Supplier

- Ethyl Undecanoate

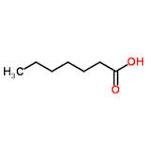

- Heptanoic Acid

- Methyl Undecanoate - Exporter

- Zinc Ricinoleate Exporter

- Glyceryl Monoricinoleate Exporter

- Glyceryl Mono Undecylenate - Exporter

- Heptyl Undecylenate Supplier

- Methyl Ricinoleate - Manufacturer

- Polyricinoleic Acid - Manufacturer

- Pentaerythritol Mono Ricinoleate- Supplier

- Ricinoleic Acid - Manufacturer

- Undecanoic Acid 98% Min. By GC

- Alcohol C-11 Undecylenic

- Methyl Undecylenate 98% Min. Purity By GC

- Undecylenic Acid

- Zinc Undecylenate as per BP/EP/USP

- Butyl Ricinoleate - Manufacturer

- Calcium Ricinoleate

- Calcium Undecylenate as per USP

- Heptaldehyde 97% Min. By GC

- Heptyl Alcohol 98%Min.By GC

- Methyl Acetyl Ricinoleate - Supplier

- Aldehyde C11 Undecylenic

- Butyl Undecylenate

- Castor Oil

- Condensed Ricinoleic Acid

- Ethyl Undecylenate

- Glyceryl Mono Undecenoate - Castor Oil Derivative

- Sodium Undecylenate

- Chromatographic Adsorbents

- Fatty Acid Esters & Salts

- Zinc Ricinoleate Supplier

- Methyl Oleate - Supplier

- Cetyl Ricinoleate Manufacturer

- Glyceryl Monoricinoleate Supplier

- Glyceryl Mono Undecylenate Manufacturer

- Heptyl Undecylenate Manufacturer

- Methyl Ricinoleate

- Pentaerythritol Mono Ricinoleate

- Butyl Oleate 99% Min. By GC

- Methyl Undecylenate - Supplier

- Butyl Ricinoleate

- Methyl Acetyl Ricinoleate - Manufacturer

- Butyl Oleate Commercial

- Methyl Oleate Commercial- Supplier

- Behenic Acid Methyl Ester

- Caprylic Acid

- Erucic Acid

- Lauric Acid

- Methyl Heptanoate

- Oleic Acid Ethyl Ester

- Palmitic Acid

- Potassium Oleate

- Sodium Caprylate - Supplier

- Soya Oil Methyl Ester

- Stearic Acid

- Arachidic Acid Ethyl Ester - Supplier

- Elaidic Acid Methyl Ester

- Glyceryl Mono Undecenoate - Supplier

- Linoleic Acid Methyl Ester 99% Min. By GC

- Methyl Undecanoate

- Palmitic Acid Methyl Ester

- Sodium Oleate

- Potassium Caprylate

- Stearic Acid Methyl Ester

- Behenic Acid Ethyl Ester

- Linoleic Acid Ethyl Ester

- Fatty Alcohols

- Lipid Chemicals

- Arachidic Acid 99% Min By GC

- Elaidic Acid 99% Min. By GC

- Linoleic Acid 99% Min. By GC

- Methyl Oleate 99% Min. By GC

- Oleic Acid 99% Min.By GC

- Methyl Oleate Commercial

- Arachidic Acid Methyl Ester

- Arachidic Acid Ethyl Ester

- Elaidyl Alcohol - Manufacturer

- Linoleyl Alcohol - Manufacturer

- Linoleic Acid Ethyl Ester - Manufacturer

- Odor Absorbers

- Ricinoleates

- Zinc Ricinoleate Manufacturer

- Cetyl Ricinoleate Exporter

- Glyceryl Monoricinoleate Manufacturer

- Methyl Ricinoleate - Supplier

- Pentaerythritol Mono Ricinoleate- Manufacturer

- Polyricinoleic Acid

- Ricinoleic Acid

- Butyl Ricinoleate - Supplier

- Calcium Ricinoleate - Manufacturer

- Methyl Acetyl Ricinoleate - Exporter

- Cosmetic Ingredients

- Undecylenic Acid - Cosmetics

- Zinc Ricinoleate

- Potassium Caprylate - Cosmetics

- Cetyl Ricinoleate

- Glyceryl Monoricinoleate

- Heptyl Undecylenate

- Undecanoic Acid - Cosmetics

- Undecylenic Monoethanolamide - Cosmetics

- Zinc Undecylenate - Cosmetics

- Methyl Acetyl Ricinoleate

- Aldehyde C11 Undecylenic - Cosmetics

- Arachidyl Alcohol - Cosmetics

- Behenic Acid Methyl Ester - Cosmetics

- Caprylic Acid - Cosmetics

- Erucic Acid - Cosmetics

- Lauric Acid - Cosmetics

- Methyl Heptanoate - Cosmetics

- Oleic Acid Ethyl Ester - Cosmetics

- Oleyl Alcohol - Cosmetics

- Palmitic Acid - Cosmetics

- Potassium Oleate - Cosmetics

- Sodium Caprylate - Cosmetics

- Soya Oil Methyl Ester - Cosmetics

- Stearic Acid - Cosmetics

- Butyl Undecylenate - Cosmetics

- Castor Oil - Cosmetics

- Glyceryl Mono Undecenoate - Cosmetics

- Heptanoic Acid - Cosmetics

- Linoleic Acid Methyl Ester - Cosmetics

- Palmitic Acid Methyl Ester - Cosmetics

- Sodium Oleate - Cosmetics

- Sodium Undecylenate - Cosmetics

- Stearic Acid Methyl Ester - Cosmetics

- Linoleic Acid Ethyl Ester - Cosmetics

- Emollient

- Cetyl Ricinoleate - Cosmetics

- Glyceryl Mono Undecylenate-Cosmetics

- Glyceryl Monoricinoleate - Cosmetics

- Heptyl Undecylenate - Cosmetics

- Methyl Acetyl Ricinoleate - Cosmetics

- Erucic Acid - Emollient

- Oleic Acid Ethyl Ester - Manufacturer

- Palmitic Acid - Exporter

- Ethyl Undecylenate - Manufacturer

- Glyceryl Mono Undecenoate - Manufacturer

- Palmitic Acid Methyl Ester - Supplier

- Stearic Acid Methyl Ester - Exporter

- Personal Care Ingredients

- Cetyl Ricinoleate - Personal Care Product

- Glyceryl Monoricinoleate- Personal Care Product

- Heptyl Undecylenate - Personal Care Product

- Methyl Acetyl Ricinoleate - Personal Care Product

- Aldehyde C11 Undecylenic - Exporter

- Arachidyl Alcohol - Manufacturer

- Behenic Acid Methyl Ester - Manufacture

- Caprylic Acid - Manufacturer

- Lauric Acid - Personal Care Product

- Oleic Acid Ethyl Ester - Personal Care Product

- Oleyl Alcohol - Manufacturer

- Palmitic Acid - Manufacturer

- Potassium Oleate - Manufacturer

- Soya Oil Methyl Ester - Manufacturer

- Stearic Acid - Manufacturer

- Palmitic Acid Methyl Ester - Manufacturer

- Sodium Oleate - Supplier

- Sodium Undecylenate - Supplier

- Natural Preservatives

- Undecylenates

- Glyceryl Mono Undecylenate-Supplier

- Heptyl Undecylenate Exporter

- Undecanoic Acid 98% Min. By GC - Manufacturer

- Sodium Undecylenate - Manufacturer

- Methyl Undecylenate 98% Min. By GC - Manufacturer

- Undecylenic Acid - Manufacturer

- Zinc Undecylenate - Manufacturer

- Calcium Undecylenate - Manufacturer

- Butyl Undecylenate - Supplier

- Castor Oil - Manufacturer

- Ethyl Undecylenate - Supplier

- Glyceryl Mono Undecenoate - Exporter

- Skin Care Products

- Glyceryl Mono Undecylenate- Skin Care Product

- Zinc Ricinoleate- Skin Care Product

- Glyceryl Monoricinoleate- Skin Care Product

- Heptyl Undecylenate - Skin Care Product

- Calcium Ricinoleate - Supplier

- Methyl Acetyl Ricinoleate - Skin Care Product

- Cetyl Ricinoleate - Skin Care Product

- Aldehyde C11 Undecylenic - Supplier

- Arachidyl Alcohol - Supplier

- Behenic Acid Methyl Ester - Supplier

- Caprylic Acid - Supplier

- Oleic Acid Ethyl Ester - Skin Care Product

- Oleyl Alcohol - Exporter

- Palmitic Acid - Supplier

- Potassium Oleate - Supplier

- Soya Oil Methyl Ester - Supplier

- Stearic Acid - Supplier

- Castor Oil - Supplier

- Glyceryl Mono Undecenoate - Skin Care Product

- Palmitic Acid Methyl Ester - Exporter

- Stearic Acid Methyl Ester - Manufacturer

- Emulsifier

- Glyceryl Monoricinoleate - Emulsifier

- Glyceryl Mono Undecylenate - Emulsifier

- Zinc Ricinoleate - Emulsifier

- Ricinoleic Acid - Emulsifier

- Undecanoic Acid - Emulsifier

- Linoleic Acid - Emulsifier

- Methyl Oleate - Emulsifier

- Oleic Acid - Emulsifier

- Undecylenic Acid - Emulsifier

- Heptaldehyde - Emulsifier

- Silica Gel for Column Chromatography - Emulsifier

- Arachidic Acid - Emulsifier

- Methyl Oleate Commercial- Emulsifier

- Caprylic Acid - Emulsifier

- Lauric Acid - Emulsifier

- Methyl Heptanoate - Emulsifier

- Oleyl Alcohol - Emulsifier

- Palmitic Acid - Emulsifier

- Potassium Oleate - Emulsifier

- Sodium Caprylate - Emulsifier

- Stearic Acid - Emulsifier

- Castor Oil - Emulsifier

- Glyceryl Mono Undecenoate - Emulsifier

- Linoleic Acid Methyl Ester - Emulsifier

- Palmitic Acid Methyl Ester - Emulsifier

- Sodium Oleate - Emulsifier

- Potassium Caprylate - Emulsifier

- Sodium Undecylenate - Emulsifier

- Stearic Acid Methyl Ester - Emulsifier

- Hair Care Products

- Heptyl Undecylenate- Hair Care Product

- Zinc Ricinoleate- Hair Care Product

- Butyl Oleate - Hair Care Product

- Linoleic Acid - Hair Care Product

- Butyl Oleate Commercial -Supplier

- Oleic Acid - Supplier

- Undecylenic Acid - Supplier

- Arachidic Acid - Hair Care Product

- Lauric Acid - Exporter

- Oleic Acid Ethyl Ester - Supplier

- Oleyl Alcohol - Supplier

- Stearic Acid - Exporter

- Sodium Undecylenate - Exporter

- Stearic Acid Methyl Ester - Supplier

- Lubricants

- Glyceryl Monoricinoleate - Lubricant

- Heptyl Undecylenate Lubricant

- Methyl Ricinoleate - Lubricant

- Polyricinoleic Acid - Lubricant

- Pentaerythritol Mono Ricinoleate - Lubricant

- Ricinoleic Acid - Lubricant

- Butyl Oleate - Lubricant

- Butyl Oleate Commercial- Lubricant

- Methyl Undecylenate - Lubricant

- Butyl Ricinoleate - Lubricant

- Methyl Acetyl Ricinoleate - Lubricant

- Behenic Acid Methyl Ester - Lubricant

- Caprylic Acid - Lubricant

- Erucic Acid - Lubricant

- Lauric Acid - Lubricant

- Oleyl Alcohol - Lubricant

- Potassium Oleate - Lubricant

- Soya Oil Methyl Ester - Lubricant

- Stearic Acid - Lubricant

- Castor Oil - Lubricant

- Heptanoic Acid - Lubricant

- Linoleic Acid Methyl Ester - Lubricant

- Palmitic Acid Methyl Ester - Lubricant

- Sodium Oleate - Lubricant

- Stearic Acid Methyl Ester - Lubricant

- Textile Chemicals

- Leather Chemicals

- Pharma Ingredients

- Zinc Undecylenate - Pharma Ingredient

- Undecylenic Acid - Pharma Ingredient

- Caprylic Acid - Pharma Ingredient

- Undecylenic Monoethanolamide

- Calcium Undecylenate - Pharma Ingredient

- Lauric Acid - Pharma Ingredient

- Sodium Caprylate - Manufacturer

- Castor Oil - Pharma Ingredient

- Heptanoic Acid - Supplier

- Sodium Oleate - Manufacturer

- Anti Fungals

- Undecylenic Acid - Antifungal

- Zinc Undecylenate - Anti Fungal

- Undecanoic Acid - Anti Fungal

- Undecylenic Monoethanolamide - Anti Fungal

- Calcium Ricinoleate - Anti Fungal

- Calcium Undecylenate - Anti Fungal

- Caprylic Acid - Anti Fungal

- Lauric Acid - Anti Fungal

- Sodium Caprylate - Anti Fungal

- Castor Oil - Anti Fungal

- Nail Care Product

- Separation Aids

- Perfumery Chemicals

- Alcohol C-11 Undecylenic - Supplier

- Methyl Undecylenate - Exporter

- Heptaldehyde - Manufacturer

- Heptyl Alcohol - Supplier

- Ethyl Undecylenate - Exporter

- Aldehyde C11 Undecylenic - Manufacturer

- Caprylic Acid - Exporter

- Methyl Heptanoate - Supplier

- Oleic Acid Ethyl Ester - Exporter

- Butyl Undecylenate - Manufacturer

- Castor Oil - Perfumery Chemical

- Ethyl Undecanoate - Manufacturer

- Linoleic Acid Methyl Ester - Exporter

- Heptanoic Acid - Manufacturer

- Methyl Undecanoate - Manufacturer

- Linoleic Acid Ethyl Ester - Exporter

- Fragrance Chemicals

- Alcohol C-11 Undecylenic - Exporter

- Heptyl Alcohol - Exporter

- Butyl Oleate - Fragrance Chemical

- Butyl Oleate Commercial - Manufacturer

- Methyl Undecylenate - Perfume & Fragrance Chemical

- Heptaldehyde - Supplier

- Aldehyde C11 Undecylenic - Perfumes & Fragrances

- Caprylic Acid - Perfumes & Fragrances

- Methyl Heptanoate - Perfumes & Fragrances

- Oleic Acid Ethyl Ester - Perfumes & Fragrances

- Castor Oil - Fragrance Chemical

- Ethyl Undecanoate - Supplier

- Ethyl Undecylenate - Perfumes & Fragrances

- Heptanoic Acid - Exporter

- Linoleic Acid Methyl Ester - Supplier

- Methyl Undecanoate - Supplier

- Linoleic Acid Ethyl Ester - Perfumes & Fragrances

- Nutritional Supplements

- Arachidic Acid - Pharmaceutical Chemical

- Elaidic Acid - Pharmaceutical Chemical

- Linoleic Acid - Pharmaceutical Chemical

- Methyl Oleate - Pharmaceutical Chemical

- Oleic Acid - Pharmaceutical Chemical

- Arachidic Acid Methyl Ester - Supplier

- Elaidyl Alcohol - Supplier

- Lauric Acid - Supplier

- Linoleyl Alcohol - Exporter

- Methyl Heptanoate - Manufacturer

- Oleic Acid Ethyl Ester - Pharmaceutical Chemical

- Oleyl Alcohol - Pharmaceutical Chemical

- Sodium Caprylate

- Linoleic Acid Methyl Ester - Manufacturer

- Specialty Fatty Acid

- Arachidic Acid - Manufacturer

- Elaidic Acid - Manufacturer

- Linoleic Acid - Manufacturer

- Methyl Oleate - Manufacturer

- Oleic Acid - Manufacturer

- Methyl Oleate Commercial - Manufacturer

- Arachidic Acid Methyl Ester - Manufacturer

- Arachidic Acid Ethyl Ester - Manufacturer

- Elaidyl Alcohol - Exporter

- Lauric Acid - Manufacturer

- Linoleyl Alcohol - Supplier

- Linoleic Acid Ethyl Ester - Supplier

- Aldehydes

- Silica Gel for Column Chromatography

- Silica Gel for Thin Layer Chroamtography

- Castor Oil Derivatives

- Contact Us

Methyl Ricinoleate - Lubricant

Product Details:

- Application High-temperature lubrication, metalworking fluids, hydraulic fluids, textile and leather lubricants

- Type Lubricant

- Weight Varies (custom packaging available)

- Color Pale yellow

- Ash % Max 0.02%

- Density 0.92 Gram per cubic centimeter(g/cm3)

- Smell Mild characteristic

- Click to view more

X

Methyl Ricinoleate - Lubricant Product Specifications

- Pale yellow

- Max 0.02%

- HDPE drum

- Varies (custom packaging available)

- Lubricant

- High-temperature lubrication, metalworking fluids, hydraulic fluids, textile and leather lubricants

- -10C to 220C

- Mild characteristic

- 0.92 Gram per cubic centimeter(g/cm3)

- Lubricating agent

- Plastic/HDPE drum

- Industrial/Automotive

- Methyl ester of ricinoleic acid (derived from castor oil)

- 32 cSt at 40C

- 200 L

- No (liquid lubricant)

- Max 0.5%

- Vegetable Ester Oil

Product Description

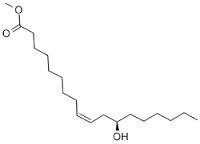

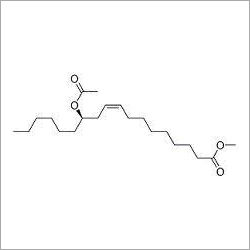

| Methyl Ricinoleate | |

| PARAMETERS | SPECIFICATIONS |

| Synonyms | RICINOLEIC ACID METHYL ESTER, METHYL ESTER OF RICINOLEIC ACID |

| CAS No. | 141-24-2 |

| Formula | C19H36O3CH3(CH2)5CH(OH)CH2-CH=CH(CH2)7 COOCH3 |

| Mol. Wt | 312.45 |

| Purity | Min. 85% Ricinoleate by GC |

| Description | Pale yellow to Dark Yellow Liquid |

| Acid Value | 3.0 Max. |

| Saponification Value | 174 - 187 |

| Iodine Value | 78 - 88 |

| Hydroxyl Value | 160 - 172 |

| Moisture | 0.75% Max. |

| Uses | Methyl Ester of Castor Oil is used in place of Castor Oil in the production of hydraulic fluids. Methyl Ricinoleate is found to be of use in ethyl cellulose, nitrile rubber, nitrous and polyvinyl butyral lacquers. |

Acme Synthetic Chemicals is the Manufacturer, Supplier & also Exporter of Methyl Ricinoleate.

Methyl Ricinoleate - Lubricant is also known as Methyl Ester of Ricinoleic Acid & Ricinoleic Acid Methyl Ester which is classified under CAS No. 141-24-2.

Acme Synthetic Chemicals is one of the reputed organizations engaged in providing superior quality Methyl Ricinoleate - Lubricant (Ricinoleic Acid Methyl Ester, CAS No.141-24-2) to our esteemed clients.

Methyl Ricinoleate - Lubricant (Ricinoleic Acid Methyl Ester, CAS No.141-24-2) is used in several lubricating formulations, cutting oils and gear oils, motor fuels, cylinder lubricants etc.

Methyl Ricinoleate - Lubricant (Ricinoleic Acid Methyl Ester, CAS No.141-24-2 ) is also used as a plasticiser in several industries such as phenolic moulding resins, spray resin systems, rubber polymers etc.

Methyl Ricinoleate - Lubricant (Ricinoleic Acid Methyl Ester, CAS No.141-24-2) delivers additional benefits of anti- rusting and corrosion.

Methyl Ricinoleate - Lubricant (Ricinoleic Acid Methyl Ester, CAS No.141-24-2 ) use as dispersing agent, mulsion stabilizer, conditioning agent, emollient in personal care products.

Methyl Ricinoleate - Lubricant (Ricinoleic Acid Methyl Ester, CAS No.141-24-2 ) use as a plasticizers in pharmaceuticals industries & as perfumery chemicals in cosmetic industries.

We can offer Methyl Ricinoleate - Lubricant (Ricinoleic Acid Methyl Ester, CAS No.141-24-2) in drums / FCL Lots and ISO Tanks.

Methyl Ricinoleate - Lubricant (Ricinoleic Acid Methyl Ester, CAS No.141-24-2 ) is packed in 190 kg HMHDPE ( plastic ) drums.

Each FCL can take 80 drums of Methyl Ricinoleate - Lubricant (Ricinoleic Acid Methyl Ester, CAS No.141-24-2).

An ISO tank can take between 18 to 20 tons of Methyl Ricinoleate - Lubricant (Ricinoleic Acid Methyl Ester, CAS No.141-24-2 ).

Our current capacity for Methyl Ricinoleate - Lubricant (Ricinoleic Acid Methyl Ester, CAS No.141-24-2 ) is 1200 tons per annum.

This Methyl Ricinoleate - Lubricant (Ricinoleic Acid Methyl Ester, CAS No.141-24-2) is widely demanded in the international market due to its high effectively, eco-friendliness & purity, and is offered in different packaging options to meet the varied needs of our clients.

The offered product Methyl Ricinoleate - Lubricant (Ricinoleic Acid Methyl Ester, CAS No.141-24-2) is formulated using supreme class ingredients and modern techniques by our team of skilled professionals as per the set industry norms at our state-of-the-art processing unit.

Versatile Industrial and Automotive Solution

Methyl Ricinoleate is designed to support a broad spectrum of lubrication needs, ranging from metalworking to textile and leather processing. Its stable viscosity and wide operating temperature range ensure reliable performance in critical, high-temperature environments.

Exceptional Purity and Stability

With a purity level above 98% and minimal ash and water content, this lubricant offers consistent quality and superior stability. The product resists oxidation and maintains its integrity, even during extended use, contributing to the longevity of machinery.

Safe & Convenient Packaging

Packaged in robust 200L HDPE drums, Methyl Ricinoleate is easy to handle and transport. The product is not classified as hazardous, making storage straightforward. Custom packaging options are available to accommodate diverse operational requirements.

FAQs of Methyl Ricinoleate - Lubricant:

Q: How is Methyl Ricinoleate used in high-temperature lubrication applications?

A: Methyl Ricinoleate is applied directly as a lubricating agent for machinery operating at temperatures between -10C and 220C. Its high flash point and stable viscosity ensure effective friction reduction and protection under demanding conditions.Q: What are the main benefits of using Methyl Ricinoleate over conventional lubricants?

A: Methyl Ricinoleate offers excellent thermal stability, low water and ash content, and high purity, resulting in prolonged equipment lifespan and reduced maintenance. Its vegetable ester composition also provides environmental advantages compared to mineral-based oils.Q: When should Methyl Ricinoleate be replaced or replenished in machinery?

A: It is recommended to follow machinery manufacturer guidelines for lubricant replacement. Generally, monitor lubricant condition regularly and replace it before the end of its 24-month shelf life or if performance decreases due to contamination or breakdown.Q: Where is Methyl Ricinoleate typically applied within various industries?

A: This lubricant finds use in industrial and automotive sectors, particularly in metalworking fluids, hydraulic oils, textile machinery, and leather processing units. It is valued especially where high-temperature performance and mild odor are necessary.Q: What is the process for storing Methyl Ricinoleate safely?

A: Store Methyl Ricinoleate in tightly sealed HDPE drums in a cool, dry area. Because it is not regulated as a hazardous material, handling is straightforward, but the product should remain protected from direct sunlight and moisture.Q: Can Methyl Ricinoleate be blended with other lubricants or additives?

A: Yes, due to its solubility in alcohol and ether, it can be formulated with compatible additives to enhance specific properties such as wear resistance or oxidation stability. Always conduct compatibility tests before large-scale blending to ensure optimal performance.Q: What packaging options are available for Methyl Ricinoleate?

A: The standard packaging is a 200-liter HDPE drum, but custom volumes and packaging types can be arranged upon request to suit diverse logistical and operational needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free